OPERATION DIRECTIONS OF FLEXIBLE RUBBER JOINTS

In order to use correctly

and safely the products, please read carefully the " Operation Directions"

before operating the products.

In additions, the " Operation Directions " must be handed to the person

in charge after completing the installation.

I. PROHIBITIONS

DON'T USE RAISED FACE FLANGES !

Please note that this products must not be put in the below-listed usages.If

the products are used against the established rules,

abnormality, mishap and malfunction may occur. We want to say in advance that trouble resulting from above oversights, this

company can not take on

the responsibility.

1. Oil and organic solvents

are prohibited from using

2. It is prohibited from

using the hot water feeding pipe

3. Use of swimming pool

water is not allowed ( circulating pump nearby pool water )

4. Do not use at the places

and fluid that may cause the basic worsening of the elasticity of the rubber.

II.ATTENTIONS FOR USAGE

1. Check to see whether the products are damaged before using with special focus on the surface of leak-resistant packing,

the interior and external

part of rubber itself. Do not use if it is damaged.

2. Scope of application.

Please confirm first the on-site maximum pressure, the maximum temperature within the scope of products specifications,

and use later Please note, if products are used beyond the specified scope, the life-span of the products may be shortened

noticeably and the leakage

may occur.

3. Correction on the value

of shift.

The allowable value of

shift of this product is expressed by the maximum value of single changed position.

4. Please make sure to confirm the switch while running operation. The wrong operation for the products because of switch-on

and operation may cause

damage.

5. Pay careful attention

to related operation. Please do not allow the running fluid to flow swiftly

and vehemently.

6. Please use this products

at a flow speed below 3m/s inside the pipe.

7. Pay attention that it does not stick to the materials such as grease, organic solvents (thinner, toluene), acid and alkali and so on.

In case they are stuck,

please wipe out immediately, and check to see whether there is abnormality in

the routine check later on.

III.ATTENTIONS FOR TRANSPORTATION

AND KEEPING

1. In the process of transportation and keeping, be careful not damage the products. In addition, please do not use the product if it

is found damaged.

2. If long keeping is required,

please avoid the direct sunshine and put it at a dark and cool place.

3. Please do not keep long

at a temperature above 40oC or at humid and moisture place.

4. Note to keep the products

from fire.

5. Do not let the products to bear the weight which results in deformation.

IV.ATTENTIONS FOR INSTALLATION

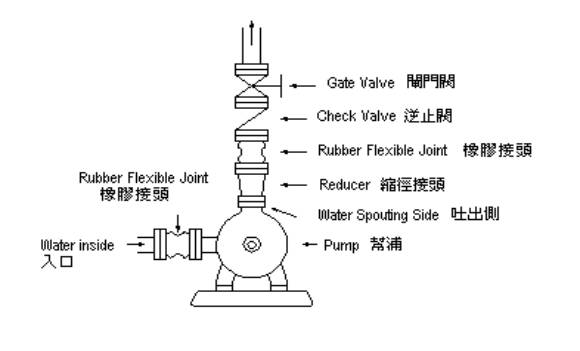

1. Please refer to the following

diagram when installing the products on hydraulic pump.

Particularly, if the preventive reversed valve is wrongly installed between the products and pump, it normally brings about the

increase in water pressure, thereby causing the earlier damage and unfitness for the products.In addition, when the products

are installed at the water-sucking place at the pump, in between the products and the piping of the reversed pump side, or at

the water-sprouting place, the pipings between the products and preventive reversed Valve should be installed each a proper

pressure gauge. Please

check often the pressure load and the status on change.

2. Please conduct installation in accordance with the allowable scope value for various value volume for extension, contraction,

eccentric circle center

point and eccentric angle

3. When the products are in use, there is national deformation and displacement, please get ready to do at the wider space and

avoid the apply of unnecessary

external force ( compression, push open, bending and rotation and so on )

4. Please ascertain the size, position and circle center for correct installation when the products are connected to the piping so

as to avoid the apply of

unnecessary external force ( compression, push open, bending and rotation and

so on ).

5. When conducting welding and fusing operation nearby after the installation, please cover all parts of the products using

incombustible film so as to avoid direct, contact with the spark. In addition, if the heat from welding and fusing may convey to

the products, please prepare

for taking down the products on temporary basis

6. Take heed of preventing

the violet ray while using outdoors.

7. You can't install rubber joint directly on the surface of valve if valve's type is Check Valve or Butterfly Valve . You must put a

reducer / adaptor between

Valve and Rubber Joint when in installation.

8. Before installing rubber joints on the pipe, System Anchoring and Pipe Guide must already have been properly installed on its

pipe.

V.ATTENTION FOR CONNECTION

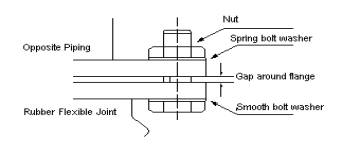

1. Based on the opposite flange shape of the products, it may damage sealed surface of the washer of the rubber itself. Please

refer to the following

table to ascertain the shape of flange.

2. While installing bolt, please insert the bolt from this side of products, and the nut is installed at opposite flange surface, in

addition, in order to prevent from slackness, make tighter installation. In addition, install spring washer Additionally, pay attention

to the front of metal screw

and bolt, do not raise them out from the flank of the products.

|

Shape |

Pipe protrude from weld – type flange |

Insert weld-type flange |

Embedded flange |

|

|

|

|

|

| |

No problem, As the internal diameter of rubber itself is at the same position with the internal diameter of opposite flange, thus with sufficient strength to cover the washer, it is highly ideal. |

Please assess whether washer is integrated for use. According to the fusing as shown in arrow 1, the sealed surface of washer may be damaged. Use the coarse file or sand paper to remove, if necessary, use together with washer. |

No way to use. The raised part as shown in arrow 2 has a small contact area with the surface of washer external film of the rubber, therefore, the load of unit area becomes larger, thus bringing about the damage of surface of washer external film and the initial water leakage. |

3. For installing the bolt, fix equally on both the diagonal line Pay attention that if the abnormal installation is done in single fixation,

it may cause the damage of the products. After fixation, determine at 900C 4 direction using fine-tuning device for the gap of

between the flange. Maintain the difference of gap's maximum value and minimum value within 0.5mm and fix equally.Gap around

flange keeps within 2 mm .

4. After the installation,

the bolt may come loose because of the vibration of pump.

Please fix equally in diagonal

line on both side.

5. Fixation related to piping

As the load of the internal pressure of the products produces reverse pressure, please be sure to fix piping in order to give the

performance of the products to full play. Especially, the front and rear fixation of the products must be fixed tighter as the

middle piping.

6. Indication of the manufacturing

year and month

The indication of manufacturing

year and month is shown in right diagram of this rubber part.

For instance, manufactured

2002 March.

7. Endurance period

The flexible rubber joint is the combined flexible body of rubber and reinforced layer.It has its life-span and is not the products of

permanent use.As the life-span of this products is subject to the influence of lots of factors, so it is no way to say the exact life-

span. This company is of

the view that the basic life-span in accordance with the below-listed average

utilization is:

1.Basic endurance years:

about 6-8 years

2.Average utilization

status

* Maximum use temperature

…………Normal temperature ( 0-800C )

* Maximum working pressure……….…225

P.S.I.G ( 15.8 kg/cm2 )

* Start and stop frequency……………..10-20

times/day

* Operating time…………………………less

than 10 hours/day

* Setting conditions……………………..Find out circle center correctly , making the state of piping at fitting state and properly

fix the supporting state.

The basic year of endurance for this products is subject to sharp change due to the lots of factors such as setting, load

status on displacement and operating hours.Therefore, the above is just a standard, Please understand this point. In

addition, in order to judge correctly the lie-span of the products and prevent the unexpected accident, please conduct

maintenance and inspection.

3.The cause of shortened

life-span

When connecting the products to the piping, be sure to determine the size, location and the right installation of circle center,

and avoid the apply of unnecessary external force ( compression, push open, bending and rotation and so on ).For long time,

please use the products under the temperature nearing the maximum applied temperature of the products.The operating

hours exceed 10 hours

one day.

The pressure change stands above 1.5 time ( maximum use pressure-typical working pressure ) and this products under the

conditions of change

in big margins.

The exposed outdoor piping

is used long time without covering by external film.

Use the products at the changed conditions.

8. Maintenance and check

The life-span of this products varies according to the usage. If the use exceeds the specified time limits, the fluid may leak and

the defect may come up.

In order to detect the

defect and abnormality in early stage, it is necessary to carry out maintenance

and check.

a.Type of check and time

of execution

1.Check after the installation

Check to make sure that installation is performed in accordance with correct established rules and keep relevant records.

The owner must hand the

recorded data to the in-charge maintenance person.

2.General check----more

than twice in a year

In order to discover the abnormality in early stage, check to ascertain the operation conditions and setting pattern of

this product.

3.Regular check

Five years after the installation, check to make sure that the abnormality not found in general check and confirm the

durability of the products.

4.Unscheduled check

This check is conducted immediately after the earthquake, fire and flooding so as to see whether the products are affected

by the disaster or not.

The durability of this product varies, depending on temperature, pressure displacement and other conditions. If the products

exceed the serviceable

period, the fluid may leak or the defect may occur.